The world of personal computing has evolved far beyond mere functionality, transforming into a realm where artistic expression meets technical prowess. Case modding represents the pinnacle of this evolution, allowing enthusiasts to create unique, personalized machines that reflect their individual style while showcasing technical mastery. Unlike simple component upgrades or basic aesthetic tweaks, true case modding involves comprehensive planning, skilled craftsmanship, and creative vision to transform ordinary computer enclosures into extraordinary works of functional art.

Modern case modding encompasses a broad spectrum of techniques, from subtle refinements that enhance existing designs to radical reconstructions that completely reimagine the computer chassis. The discipline requires understanding of materials science, electronics, thermal dynamics, and aesthetic principles, combined with practical skills in fabrication, painting, and assembly. Successful modders develop expertise across multiple domains, enabling them to realize complex visions that seamlessly blend form and function.

The motivation for case modding extends beyond mere customization. Enthusiasts seek to create machines that stand apart from mass-produced alternatives, expressing personality through carefully crafted details and innovative solutions. Professional modders often push boundaries of conventional design, developing techniques and approaches that influence mainstream computer case design. The community aspect of modding culture fosters continuous innovation, with builders sharing techniques, inspiration, and collaboration that drives the discipline forward.

Foundation Planning and Design Philosophy

Every successful case modification begins with thorough planning that considers both aesthetic goals and functional requirements. The planning phase establishes project scope, identifies technical challenges, and develops solutions that maintain system reliability while achieving desired visual impact. Professional modders invest significant time in this preparatory stage, recognizing that careful planning prevents costly mistakes and ensures successful outcomes.

Design philosophy plays a crucial role in guiding modification decisions. Some modders pursue minimalist aesthetics that emphasize clean lines and subtle enhancements, while others embrace maximalist approaches featuring bold colors, complex lighting arrangements, and dramatic structural modifications. Understanding personal aesthetic preferences helps focus design decisions and maintain coherent visual themes throughout the modification process.

Theme development requires consideration of multiple factors including color palettes, material selections, lighting concepts, and structural modifications. Successful themes maintain consistency across all modification elements, creating cohesive designs that feel intentional rather than haphazard. Whether pursuing futuristic sci-fi aesthetics, industrial steampunk themes, or elegant minimalist designs, maintaining thematic consistency separates professional-quality modifications from amateur attempts.

Functional requirements must balance aesthetic desires with practical limitations. Thermal management considerations influence ventilation modifications, structural changes must maintain component accessibility, and aesthetic enhancements cannot compromise system reliability. Experienced modders develop skills in evaluating these trade-offs, finding creative solutions that achieve visual goals without sacrificing performance or usability.

Budget planning involves more than simple cost estimation. Professional modifications require investments in quality tools, materials, and sometimes specialized equipment. Understanding cost implications early in the planning process helps establish realistic project scope and prevents mid-project compromises that could undermine final results. Successful modders often phase complex projects across multiple stages, allowing for budget management while maintaining momentum toward completion.

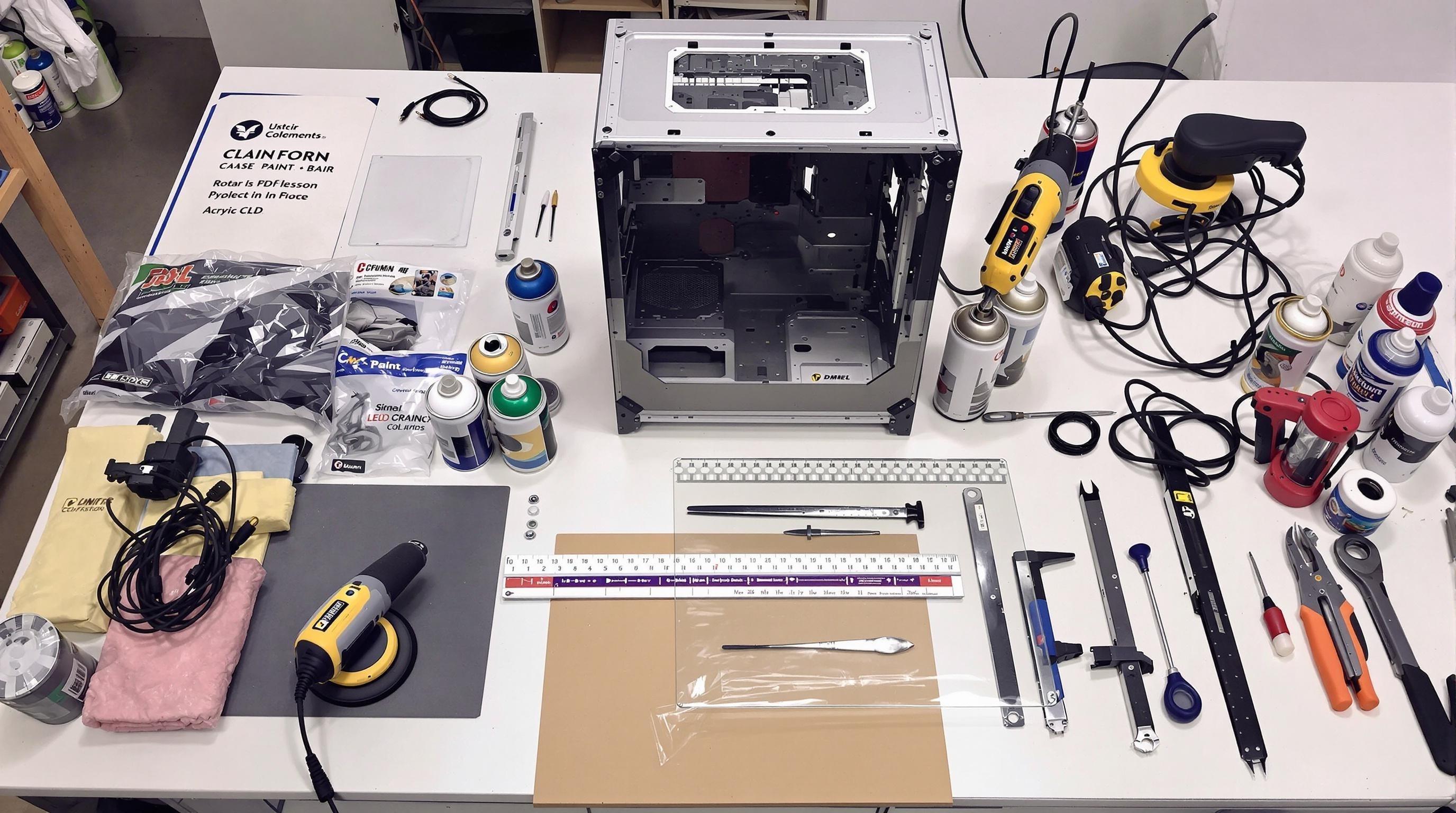

Essential Tools and Workshop Preparation

Professional case modding demands appropriate tools and workspace preparation to achieve quality results safely and efficiently. The tool selection directly impacts modification quality, with precision instruments enabling clean cuts, smooth finishes, and professional-grade assembly. Building a comprehensive tool collection represents a significant investment, but quality instruments provide years of reliable service across multiple projects.

Cutting tools form the foundation of most modification projects. Rotary cutoff tools enable precise cuts in sheet metal, while reciprocating saws handle heavier structural work. Fine-toothed hand saws provide control for delicate operations, and various cutting blades accommodate different materials from aluminum to acrylic. Sharp, high-quality cutting tools produce clean edges that require minimal finishing work, saving time and improving final appearance.

Shaping and finishing tools refine cut edges and prepare surfaces for painting or other treatments. Files and sandpaper in various grits smooth rough edges and remove manufacturing marks. Power sanders accelerate surface preparation for large areas, while hand sanding provides control for detailed work. Understanding proper grit progression and sanding techniques prevents scratches and ensures smooth, professional finishes.

Drilling equipment enables precise hole placement for mounting hardware, ventilation, and cable management. Variable-speed drills accommodate different materials and bit types, while drill presses provide accuracy for critical holes. Step bits create clean holes in sheet metal, and hole saws cut larger openings for fans or cable grommets. Sharp, appropriate bits prevent material damage and ensure clean, accurate results.

Measurement and marking tools ensure accuracy throughout the modification process. Quality rulers, squares, and calipers enable precise layout work, while scribes and awls create accurate reference marks. Digital calipers measure component dimensions and verify clearances, preventing interference issues during assembly. Templates and patterns help replicate complex shapes and maintain consistency across multiple cuts.

Safety equipment protects against injury during modification work. Eye protection prevents debris from cutting and grinding operations, while respiratory protection shields against dust and chemical vapors. Hearing protection reduces damage from power tool noise, and proper lighting prevents accidents while improving work quality. Fire extinguishers and first aid supplies provide emergency response capabilities for workshop accidents.

Surface Preparation and Painting Techniques

Surface preparation forms the foundation of professional painting results, with proper technique determining finish quality and durability. Amateur modifications often fail due to inadequate preparation, while professional results depend on methodical surface treatment that ensures optimal paint adhesion and smooth, uniform coverage. Understanding material properties and appropriate preparation techniques enables consistently superior finishes across different substrates.

Metal surfaces require specific preparation sequences depending on existing finishes and desired outcomes. Factory powder coating must be completely removed through chemical stripping or aggressive sanding to ensure new paint adhesion. Raw aluminum surfaces need degreasing and light abrasion to provide tooth for primer adhesion. Steel components may require rust removal and protective primer application to prevent future corrosion under the finish coat.

Chemical preparation involves degreasing agents that remove manufacturing oils, fingerprints, and other contaminants that prevent proper paint adhesion. Appropriate solvents vary with substrate materials, with some plastics requiring specific cleaners that will not cause chemical damage. Tack cloths remove residual dust and lint immediately before painting, ensuring clean surfaces for optimal results.

Primer selection depends on substrate material and intended topcoat characteristics. High-build primers fill minor surface imperfections and provide uniform color base for subsequent coats. Adhesion promoters ensure proper bonding between dissimilar materials, particularly important when painting plastic components. Specialized primers accommodate specific requirements such as chemical resistance or thermal stability.

Spray technique directly affects finish quality, with consistent motion and proper overlap creating smooth, uniform coverage. Maintaining appropriate distances prevents runs and sags while ensuring adequate material deposition. Multiple thin coats produce superior results compared to single heavy applications, building depth and richness while minimizing defects. Environmental conditions including temperature and humidity significantly impact application success and cure characteristics.

Color theory guides paint selection and combination decisions for complex schemes. Understanding color relationships helps create pleasing palettes that enhance rather than clash with component colors. Metallic finishes require special techniques to achieve uniform appearance, while custom color matching enables precise coordination with specific components or themes. Clear coat application protects base colors while providing depth and gloss control.

Advanced Lighting Integration

Lighting represents one of the most dramatic modification categories, transforming case interiors from dark, utilitarian spaces into spectacular showcases for high-end components. Modern lighting technology offers unprecedented control over color, intensity, and effects, enabling modders to create sophisticated illumination schemes that enhance component visibility while contributing to overall aesthetic impact. Professional lighting integration requires understanding of electrical principles, color theory, and visual design to achieve optimal results.

Light-emitting diode technology has revolutionized case lighting through efficiency, longevity, and versatility advantages over traditional alternatives. Modern LEDs generate minimal heat while providing brilliant illumination in virtually any color combination. Programmable controllers enable dynamic effects including color cycling, music synchronization, and temperature-responsive changes that add interactive elements to static displays. Understanding LED characteristics and control options enables sophisticated lighting designs previously impossible with conventional technology.

Color temperature selection significantly impacts visual appearance of illuminated components. Cool white lighting emphasizes metal surfaces and creates clinical, high-tech atmospheres, while warm white produces more inviting, comfortable environments. Colored lighting can enhance specific components or create thematic ambiance, but requires careful selection to avoid overwhelming effects or unflattering color combinations. Professional installations often incorporate multiple color temperatures and control zones for maximum flexibility.

Placement strategy determines lighting effectiveness and visual impact. Direct illumination creates strong highlights and sharp shadows that emphasize component details and create dramatic contrasts. Indirect lighting provides even illumination that reveals overall system organization without harsh shadows. Accent lighting highlights specific components or features, drawing attention to premium parts or custom modifications. Combining multiple placement strategies creates depth and visual interest while avoiding flat, uniform illumination.

Control systems range from simple switches to sophisticated computer-controlled networks that enable complex programming and synchronization. Basic installations may use manual controls for static colors and simple effects, while advanced systems integrate with system monitoring to provide real-time feedback through lighting changes. Wireless control enables remote adjustment without physical access to the system, particularly valuable for display installations or systems with limited physical access.

Power distribution and electrical safety require careful attention in lighting installations. LED strips and individual modules have specific voltage and current requirements that must be met for proper operation and longevity. Power supplies must provide adequate capacity with appropriate regulation and protection features. Wiring must handle required currents safely while maintaining neat appearance that complements overall modification aesthetics. Professional installations include fusing and switching that enable maintenance and troubleshooting without system shutdown.

Custom Panel Fabrication and Modification

Panel modification and fabrication enable dramatic structural changes that distinguish professional modifications from simple aesthetic enhancements. Creating custom panels requires understanding of materials, fabrication techniques, and structural engineering to ensure modifications maintain case integrity while achieving desired visual impact. Whether replacing existing panels with custom alternatives or adding entirely new elements, panel work demands precision and attention to detail that separates amateur attempts from professional results.

Material selection influences both fabrication techniques and final appearance characteristics. Aluminum sheet provides excellent workability and strength for structural applications, while maintaining compatibility with standard fasteners and joining methods. Acrylic materials enable transparent or translucent panels that showcase internal components while protecting against contamination. Steel offers superior strength for heavy-duty applications but requires specialized cutting and finishing techniques.

Template creation ensures accuracy and repeatability in panel fabrication. Professional modders develop detailed templates using cardboard or thin sheet materials before cutting expensive final materials. Computer-aided design tools enable precise measurements and complex curves that would be difficult to achieve through manual layout methods. Three-dimensional printing creates complex templates for curved or sculpted panels that require precise matching to existing case geometry.

Cutting techniques vary with material properties and desired edge characteristics. Plasma cutting provides fast, clean cuts in metal materials but requires significant equipment investment and safety precautions. Water jet cutting produces extremely precise edges without heat-affected zones but typically requires commercial services for hobbyist projects. Manual cutting using appropriate hand tools provides flexibility and control but demands higher skill levels for professional results.

Edge finishing transforms rough cut edges into clean, professional appearances that complement overall modification quality. File work removes cutting marks and establishes smooth, uniform edges that resist corrosion and provide safe handling characteristics. Progressive sanding creates polished edges that catch and reflect light, adding visual interest to panel transitions. Decorative edge treatments including bevels and chamfers create sophisticated details that elevate overall appearance quality.

Mounting system design must accommodate panel attachment while maintaining structural integrity and aesthetic appeal. Hidden fastener systems create clean appearances without visible hardware interrupting visual flow. Magnetic mounting enables easy panel removal for maintenance access while providing secure attachment during normal operation. Custom brackets and mounting hardware may require fabrication to achieve proper fit and appearance with modified case geometry.

| Material Type | Best Applications | Cutting Method | Finishing Requirements |

| Aluminum Sheet | Structural panels, custom frames | Plasma, jigsaw, metal cutting | Deburring, sanding, anodizing optional |

| Acrylic/Polycarbonate | Windows, transparent panels | Laser cutting, fine-tooth saw | Edge polishing, flame polishing |

| Steel Sheet | Heavy-duty applications | Plasma, angle grinder | Rust prevention, primer, paint |

| Carbon Fiber | Decorative panels, lightweight applications | Diamond blade, fine saw | Edge sealing, clear coat protection |

Thermal Management and Airflow Optimization

Successful case modifications must maintain or improve thermal performance while achieving aesthetic goals. Understanding airflow principles and heat transfer mechanisms enables modders to make informed decisions about structural changes that affect cooling performance. Professional modifications often improve thermal characteristics through strategic ventilation additions and airflow optimization that enhance both performance and visual appeal.

Airflow fundamentals govern cooling effectiveness in computer systems. Cool air intake and heated air exhaust must maintain positive pressure relationships that prevent dust accumulation while ensuring adequate air circulation across critical components. Modifications that interrupt established airflow patterns can create hot spots or recirculation zones that compromise cooling effectiveness. Understanding these principles guides modification decisions that maintain thermal performance.

Ventilation planning requires analysis of existing airflow patterns and identification of improvement opportunities. Strategic placement of additional intake and exhaust openings can improve cooling performance while creating visual interest through custom grilles or decorative treatments. Fan mounting modifications may enable larger or more efficient cooling solutions that reduce noise while improving temperature control. Dust filtration integration maintains system cleanliness without significantly restricting airflow.

Component spacing considerations become critical when modifying internal layouts or adding custom elements. Graphics cards, processors, and power supplies generate significant heat that must be effectively removed through adequate airflow. Custom mounting solutions should maintain manufacturer-recommended clearances while ensuring air circulation paths remain unobstructed. Thermal imaging can verify modification effectiveness and identify potential problem areas before they cause component damage.

Custom ducting and air channeling can direct cooling air precisely where needed while creating unique visual elements. Fabricated ducts can guide intake air directly to specific components or channel heated exhaust away from sensitive areas. Transparent ducting materials showcase airflow while maintaining functional effectiveness. Integration with lighting systems can create dramatic effects that highlight cooling system operation.

Temperature monitoring integration enables verification of modification effectiveness and early identification of potential problems. Digital temperature sensors can be strategically placed to monitor critical components and overall system thermal performance. Data logging capabilities track temperature trends over time, identifying gradual changes that might indicate developing problems. Integration with lighting systems can provide visual feedback about system thermal status through color-coded displays.

Cable Management and Wiring Aesthetics

Professional cable management transforms utilitarian wiring installations into clean, organized displays that complement overall modification aesthetics. Beyond simple bundling and routing, advanced cable management involves custom fabrication, color coordination, and integration with other modification elements to create cohesive, professional appearances. Proper techniques improve both visual appeal and functional reliability while facilitating future maintenance and upgrades.

Routing strategy development begins with understanding power and signal requirements for all system components. Primary power connections require heavy-gauge wiring that may be difficult to conceal or redirect, while signal cables offer more flexibility in routing and management. Separating power and signal wiring prevents electromagnetic interference while enabling independent routing that optimizes both function and appearance.

Custom cable fabrication enables precise length control and color coordination that mass-produced alternatives cannot achieve. Individual wire selection allows exact length matching and eliminates excess material that creates bulk and visual clutter. Heat-shrink tubing and cable sleeves provide professional appearance while protecting conductors from damage. Connector assembly requires appropriate tools and techniques to ensure reliable connections that maintain signal integrity.

Sleeve selection affects both appearance and functionality of cable installations. Braided sleeves provide flexible protection with professional appearance that complements high-end component aesthetics. Split sleeves enable easy installation over existing connections while maintaining neat appearance. Colored sleeves coordinate with modification themes while providing visual organization for different circuit types. Heat-resistant materials ensure durability near high-temperature components.

Anchor point planning establishes routing paths that maintain organization while preventing cable stress or interference with moving components. Cable ties and mounting hardware must support cable weight without creating stress concentrations that could cause conductor damage. Removable fastening systems enable maintenance access without destroying cable organization. Strategic anchor placement maintains cable organization while allowing for component removal and replacement.

Integration with modification elements incorporates cable management into overall aesthetic schemes rather than treating it as separate consideration. Custom panels can include integrated cable routing channels that maintain organization while enhancing visual appeal. Lighting integration can illuminate cable runs to create dramatic effects or provide functional work lighting. Color coordination with other modification elements creates cohesive appearances that demonstrate attention to detail.

Specialized Techniques and Advanced Methods

Advanced case modding incorporates specialized techniques that distinguish expert-level modifications from basic customization projects. These methods require significant skill development and often specialized equipment, but enable transformative results that would be impossible through conventional approaches. Mastering advanced techniques opens possibilities for truly unique modifications that push creative boundaries while maintaining functional excellence.

Water cooling integration represents one of the most technically challenging modification categories, requiring understanding of fluid dynamics, thermal management, and precision fabrication. Custom cooling loops enable dramatic visual effects through colored coolants and transparent tubing while providing superior thermal performance compared to air cooling alternatives. Hard-line tubing installations create sculptural elements that serve as functional art within the modified case. Proper implementation requires careful planning to prevent leaks that could destroy expensive components.

Scratch building involves creating entirely custom cases from raw materials rather than modifying existing enclosures. This approach provides complete design freedom but requires advanced fabrication skills and substantial tool investments. Scratch-built cases can incorporate features and proportions impossible with commercial alternatives, enabling perfect integration with specific component requirements or aesthetic visions. Professional scratch builds often become showcase pieces that demonstrate the highest levels of modding skill.

Three-dimensional printing technology enables creation of complex custom components that would be impossible through traditional fabrication methods. Custom brackets, decorative elements, and functional components can be designed and produced with precise tolerances and complex geometries. Advanced printing materials including metal-filled filaments and engineering plastics provide strength and durability for functional applications. Integration of printed components with traditional materials creates hybrid solutions that combine advantages of both approaches.

Electronics integration incorporates custom circuits and microcontrollers that enable sophisticated control and monitoring capabilities. Temperature sensing, fan control, and lighting management can be automated through custom electronics that respond to system conditions. Display integration can provide real-time system monitoring through custom LCD or LED installations. Advanced projects may incorporate wireless connectivity and smartphone integration for remote monitoring and control capabilities.

Artistic techniques borrowed from other disciplines can enhance modification aesthetics through unique surface treatments and visual effects. Airbrushing enables complex color gradients and artistic designs that surpass simple solid color schemes. Etching and engraving create permanent decorative elements in metal and acrylic surfaces. Specialized finishing techniques including powder coating and anodizing provide durable, professional-quality surface treatments that resist wear and environmental damage.

| Technique Category | Skill Level Required | Equipment Investment | Typical Project Duration |

| Basic Painting | Beginner | Low to Moderate | 1-2 weeks |

| Custom Panels | Intermediate | Moderate | 2-4 weeks |

| Water Cooling | Advanced | High | 4-8 weeks |

| Scratch Building | Expert | Very High | 2-6 months |

| Electronics Integration | Expert | High | 1-3 months |

Troubleshooting and Problem Resolution

Even carefully planned modifications encounter unexpected challenges that require creative problem-solving and technical expertise to resolve. Understanding common problems and their solutions enables modders to address issues quickly and effectively, preventing project delays and maintaining modification quality. Professional modders develop troubleshooting skills through experience and systematic approaches to problem identification and resolution.

Fitment issues represent the most common modification challenges, occurring when custom components do not align properly with existing case geometry or interfere with standard components. Careful measurement and template verification during planning stages can prevent many fitment problems, but modifications often reveal unexpected conflicts that require creative solutions. Adjustment techniques including filing, shimming, and bracket modification can resolve minor fitment issues without compromising overall project integrity.

Paint and finish problems can ruin the appearance of otherwise successful modifications, making prevention and correction techniques essential knowledge for serious modders. Poor adhesion typically results from inadequate surface preparation or contamination during application. Runs and sags indicate incorrect spray technique or environmental conditions during application. Understanding correction techniques including sanding and recoating enables recovery from finish problems without starting over completely.

Electrical issues in lighting and control systems can create safety hazards while preventing proper system operation. Overloaded circuits may cause component damage or create fire hazards, making proper electrical design and installation critical for safe operation. Intermittent connections create unreliable operation that can be difficult to diagnose and correct. Systematic troubleshooting approaches using multimeters and other test equipment enable identification and resolution of electrical problems.

Thermal problems may not become apparent until after modification completion, making prevention through proper planning essential for successful projects. Blocked airflow paths can create component overheating that damages expensive hardware. Poor thermal interface materials or improper cooling system installation can reduce thermal performance despite adequate airflow. Temperature monitoring during initial operation enables early identification of thermal issues before they cause permanent damage.

Structural integrity concerns may develop if modifications remove too much material or create stress concentrations that weaken case construction. Vibration from cooling fans can reveal structural weaknesses that were not apparent during static testing. Heavy components may require additional support structures to prevent deflection or damage over time. Understanding structural principles and appropriate reinforcement techniques enables resolution of strength issues without compromising aesthetic goals.

Professional case modding represents the convergence of technical skill, artistic vision, and meticulous execution that transforms ordinary computer enclosures into extraordinary expressions of creativity and craftsmanship. The discipline demands continuous learning and skill development across multiple domains, from basic fabrication techniques to advanced electronics integration. Successful modders develop comprehensive capabilities that enable realization of complex visions while maintaining the functional excellence that modern computing demands.

The evolution of modding culture continues to push creative boundaries while advancing technical capabilities that influence mainstream computer design. Professional modders often pioneer techniques and approaches that eventually find their way into commercial products, demonstrating the innovative power of enthusiast communities. The sharing of knowledge and techniques through online communities and competitions fosters continuous advancement that benefits the entire modding ecosystem.

Future developments in materials, tools, and manufacturing technologies will undoubtedly expand the possibilities for case modification while potentially reducing barriers to entry for new practitioners. Three-dimensional printing, advanced materials, and increasingly sophisticated control systems promise to enable modifications that surpass current capabilities while maintaining the hands-on satisfaction that draws enthusiasts to the discipline.

The investment required for serious case modding extends beyond monetary considerations to include significant time and effort in skill development and project execution. However, the satisfaction of creating unique, personalized systems that perfectly express individual aesthetic preferences and technical requirements provides rewards that far exceed the costs involved. Professional-quality modifications create lasting satisfaction while demonstrating technical capabilities that often lead to career opportunities in related fields.

Understanding the principles and techniques outlined in this comprehensive guide provides the foundation for successful case modification projects that achieve professional results while maintaining system reliability and performance. Whether pursuing subtle enhancements or radical transformations, systematic application of proper planning, quality materials, and skilled execution enables realization of ambitious modification goals that create truly exceptional computer systems worthy of display and admiration.

pc-add-ons.com

pc-add-ons.com